Newsroom

.svg)

Thank you! Your submission has been received!

Oops! Something went wrong while submitting the form.

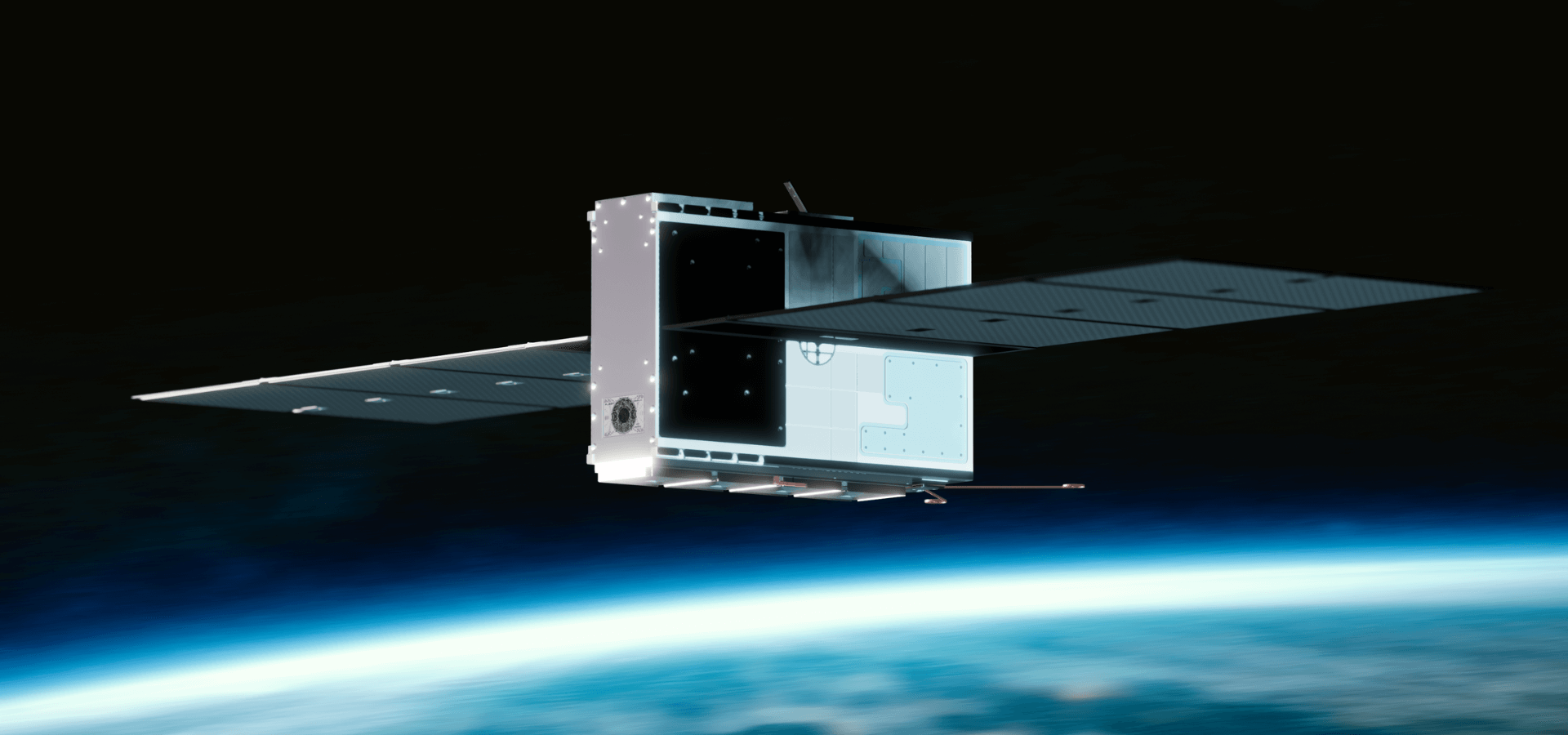

Fleet Space Launches Next-Gen Centauri-6 Satellite on SpaceX’s Bandwagon-1 Mission

April 8, 2024

Press Release

Fleet Space Technologies announced the successful deployment of its next-generation Centauri-6 satellite on SpaceX’s Bandwagon-1 mission, launched aboard a SpaceX Falcon 9 from Launch Complex 39A at the Kennedy Space Center in Florida. To the stars again!

Learn more

Space

PDAC 2024: Fleet Space’s View from the Heights of Mineral Exploration

March 15, 2024

Blog

Fleet Space was honoured to have a significant presence at PDAC 2024 – standing alongside global mining leaders to discuss the challenges and opportunities ahead for exploration on the journey to net-zero. Read more about our experience at this year’s PDAC and how we’re unlocking new possibilities for the mineral exploration industry with ExoSphere.

Learn more

Minerals

ExoSphere

Fleet Space’s Centauri Becomes Earth’s Smallest Voice-Capable Satellite After In-Orbit Software Update

March 12, 2024

Press Release

Fleet Space successfully demonstrated satellite-enabled Push-to-Talk (PTT) capabilities for the Australian Defence Force Joint Capabilities Group as part of their ASCEND2LEO program making Centauri-4 the world’s smallest known voice-enabled satellite.

Learn more

Defence

Space

CEO Reflections: International Women’s Day

March 8, 2024

Blog

“The bravery, persistence, and determination of women around the world is bending the arc of our future toward greatness.“ – Co-Founder & CEO , Flavia Tata Nardini, shares her reflections on International Women’s Day and insights from her journey building Fleet Space Technologies.

Learn more

Corporate

People

Power Nickel CEO: Spacetech Brings Mineral Exploration’s Future into Focus

March 4, 2024

Blog

Power Nickel is leveraging Fleet Space’s ExoSphere technology to accelerate the exploration of their projects in Canada and Chile. Learn more about how Power Nickel’s use of ExoSphere is propelling their vision to become the world’s first carbon-neutral Nickel mining operation.

Learn more

Minerals

ExoSphere

.png)

Fleet Space & Stanford University’s Mineral-X Partner to Advance Space-Enabled Climate Innovation

March 4, 2024

Press Release

Fleet Space Technologies announced a partnership with Stanford University’s Mineral-X program – a premiere global research organization with deep expertise in geoscience and artificial intelligence – to advance research, unlock innovation and accelerate humanity’s clean energy future leveraging space technology.

Learn more

Minerals

ExoSphere

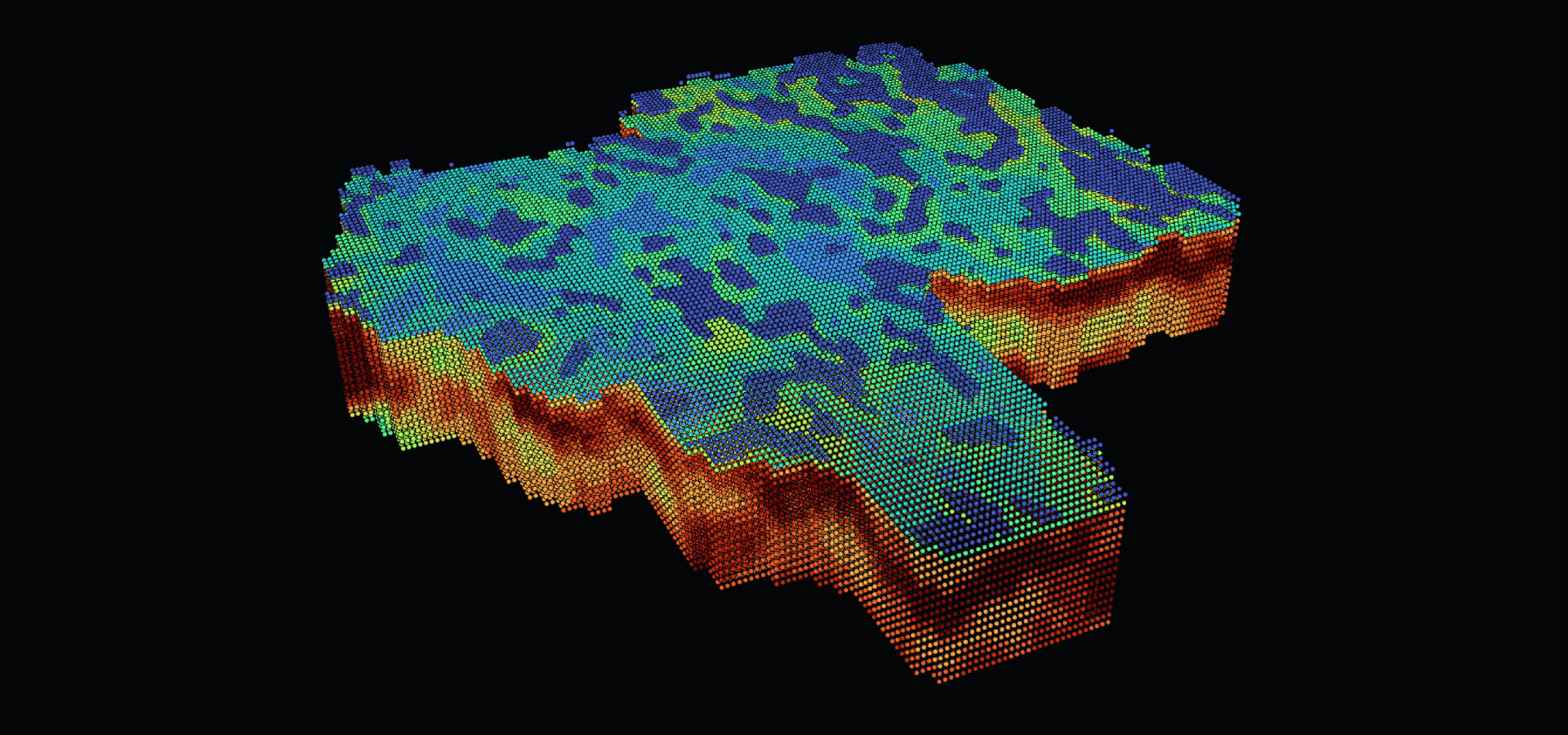

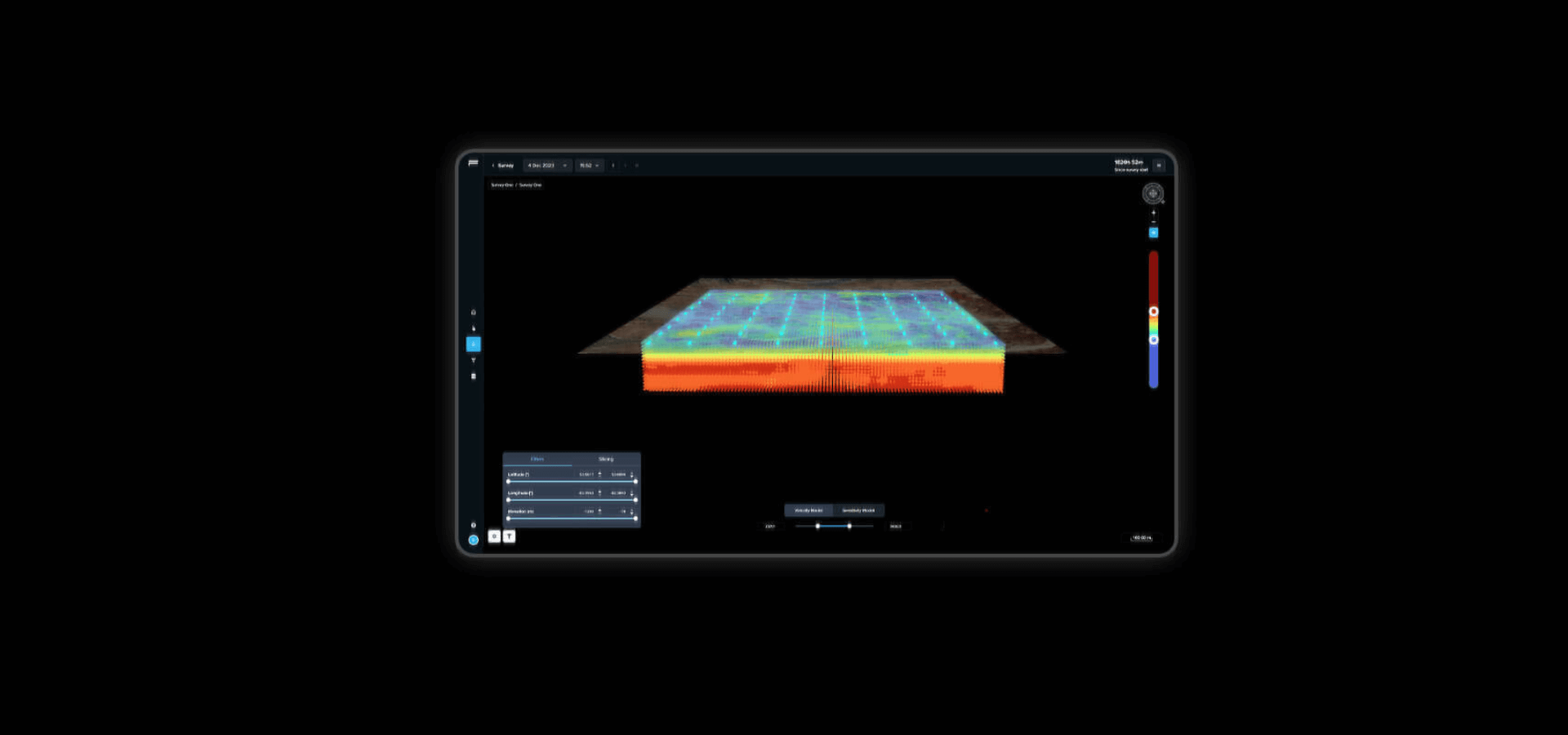

Fleet Space Announces New ExoSphere Features to Advance ML-Enabled, Real-Time Exploration

March 4, 2024

Press Release

Fleet Space Technologies announced three new features to their mineral exploration technology, Exosphere by Fleet® – designed to enhance and accelerate data-driven global mineral exploration efforts with machine learning (ML) capabilities and real-time survey diagnostics.

Learn more

ExoSphere

Fleet Space Launches Expert-in-Residence Program with Appointment of Former BHP, VP Keenan Jennings

February 13, 2024

Press Release

Fleet Space Technologies, a global leader in space-enabled mineral exploration, today announced former BHP, VP Keenan Jennings as the first appointee to the company’s Experts-In-Residence (XIR) program.

Learn more

Minerals

Fleet Space’s Growth Continues with Multiple Strategic Appointments

January 18, 2024

Blog

Fleet Space Technologies, a global leader in space-enabled mineral exploration, is excited to announce four strategic appointments across the business, continuing its exponential growth into 2024.

Learn more

People

Fleet Space 2023: A Journey of Exponential Growth

December 20, 2023

Blog

As we look up to reflect on our progress in 2023, Fleet’s exponential growth, innovation, collaboration, and global impact marks a monumental stride forward as we continue our journey to the stars.

Learn more

Corporate

Fleet Space CEO Flavia Tata Nardini Elected to Austmine Board of Directors

December 13, 2023

Press Release

Fleet’s CEO and Co-founder, Flavia Tata Nardini, has been appointed to Austmine’s Board of Directors.

Learn more

Corporate

Fleet Space Technology Helps Lead the Expansive Search for Critical Minerals

December 3, 2023

Fleet in the Media

George Downs of The Wall Street Journal explores the extensive search for EV battery minerals from the ocean floor to space.

Learn more

Minerals

Fleet Space Technology Named Fastest Growing Company in Australia

November 29, 2023

Fleet in the Media

Fleet has topped The Australian Financial Review’s Fast 100 list for 2023 with a compound annual growth rate of 582 per cent over three years.

Learn more

Corporate

Fleet Space's SPIDER Propels Lunar Exploration with Firefly's Blue Ghost Lander

November 10, 2023

Fleet in the Media

Discover how SPIDER's innovative design tackles the challenges of the lunar environment, offering insights into the Moon's subsurface composition and the potential for sustaining human life beyond Earth.

Learn more

Space

Fleet’s Lunar Seismic Technology Heads to the Moon on Firefly’s Blue Ghost Lander

November 9, 2023

Press Release

Fleet Space's SPIDER seismic technology will land on the Moon’s surface on Firefly Aerospace’s lunar mission in 2026.

Learn more

Space

Fleet Space Technology's Moon Venture Set to Propel Discovery to Greater Depths

November 8, 2023

Fleet in the Media

Fleet Space Technologies' SPIDER's seismic exploration promises insights into lunar subsurface and future infrastructure possibilities, marking a significant step towards human expansion beyond Earth.

Learn more

Space

Fleet Announces New ExoSphere Product Features To Accelerate Global Mineral Exploration

October 31, 2023

Press Release

Fleet Space announced three new features for Exosphere - enhancing the agility and accuracy of data-driven exploration efforts worldwide.

Learn more

ExoSphere

Greater Data Intelligence Now Available from ExoSphere by Fleet®

October 30, 2023

Fleet in the Media

New features now deliver more significant insights into ambient noise conditions, data quality and confidence levels.

Learn more

Minerals

ExoSphere

Why Space is Transforming How We Mine

October 25, 2023

Fleet in the Media

Merging mining and space technology is the new frontier to fast-track mineral exploration, as discussed at the 2023 IMARC in Sydney.

Learn more

Minerals

ExoSphere

Space

Fleet Space Technologies Appoints Imelda Alexopoulos as Director of Exploration Strategy

September 28, 2023

Blog

Imelda Alexopoulos takes on role as Director of Exploration Strategy at Fleet Space, aiding the company's ambitious growth in space and terrestrial exploration.

Learn more

Space

People

Fleet Space Technologies takes stake in Thor Energy underpinning long-term commitment to revolutionising mineral exploration at Alford East project

September 4, 2023

Press Release

Fleet partners with Thor Energy, using progressive ExoSphere by Fleet® technology for exploration at the Alford East Copper-REE Project, demonstrating a sustainable shift in the industry.

Learn more

ExoSphere

Minerals

Fleet Space Welcomes Chief People Officer Amid Rapid Growth Following Series C Funding Round

August 29, 2023

Blog

Fleet Space Technologies welcomes Isa Notermans as Chief People Officer. The addition marks a growth phase after a successful Series C funding round.

Learn more

People

Fleet Space Continues Global Expansion with First Acquisition of European Frequency Assets

July 20, 2023

Press Release

Fleet Space announces its first acquisition in Europe, acquiring frequency assets key for its global satellite services and bolstering its international growth.

Learn more

Space

.png)

Dr. Matteo Genna joins Fleet Space Technologies as Chief Technology Officer

July 5, 2023

Blog

Dr. Matteo Genna, the new CTO, to drive innovation and the technical roadmap for Fleet’s satellite-enabled solutions.

Learn more

People

Moon Landing Preparations Underway for Fleet Space Technology

June 29, 2023

Fleet in the Media

Fleet Space Technology plans to deploy its SPIDER seismic payload on the moon to continuously record moonquakes for up to 14 days, aiming to be one of the first Australian technology to achieve this milestone in lunar exploration.

Learn more

Space

We’re Going to the Moon! Fleet Space Awarded A$4M Demonstrator Program Contract to Harness Seismic Data at Moon’s South Pole

June 28, 2023

Press Release

Fleet Space wins A$4M Demonstrator Program contract to harness seismic data technology for Lunar and Martian exploration.

Learn more

Space

Fleet Space appoints Darren Burrows as Senior Exploration Geophysicist

June 8, 2023

Blog

Geophysics expert, Darren Burrows, appointed as Senior Exploration Geophysicist at Fleet Space, a key role in the company's global expansion.

Learn more

People

Fleet Space Raises A$50M Series C to Globalise Revolutionary Critical Minerals Exploration Tech

May 24, 2023

Press Release

Fleet Space Technologies secures A$50M in Series C funding, boosting the global expansion of its groundbreaking satellite-based mineral exploration technology, ExoSphere by Fleet®

Learn more

Corporate

$33 Million Raised in Series C Funding Round for Fleet Space Technology

May 24, 2023

Fleet in the Media

The funding will enhance its satellite-based mineral exploration services, focusing on expanding its Exosphere mineral prospecting business, especially in North America.

Learn more

Corporate

Fleet Ventures into the Defence Sector, Marking a New Frontier

April 21, 2023

Fleet in the Media

Fleet Space Technologies has entered into a $6.4 million agreement with Australia’s Defence Space Command, marking their debut in the defence sector.

Learn more

Defence

Fleet Space Technologies Secures Australian Defence Space Command Contract

April 20, 2023

Press Release

Fleet Space Technologies signs AUD$6.4 million contract with Australia’s Defence Space Command.

Learn more

Defence

Fleet Space Technologies Boosts Leadership Team with New CMO Appointment as it Sets its Sights on Growth

March 15, 2023

Blog

Chloe Leclerc joins Fleet Space as CMO, delivering on a global marketing strategy to drive growth and inspire more women in the space sector.

Learn more

People

Infinity Mining and Fleet Space Technologies Take the Search for Essential Elements to New Depths at Tambourah South

February 16, 2023

Blog

Infinity Mining and Fleet Space Technologies take the search for essential elements to new depths at Tambourah South. Learn More.

Learn more

Minerals

New Fleet Space Partnership Heralds First ExoSphere by Fleet® Deployment in Canada

February 1, 2023

Press Release

Fleet Space partners with Power Nickel to use ExoSphere by Fleet® to expedite nickel-ore discovery in Canada, revolutionising mineral exploration

Learn more

Minerals

Fleet Space Technologies: A Global 100+ Employee Team

December 6, 2022

Blog

Fleet Space has reached a significant milestone: we’re now employing over 100 people from around the world, proudly representing 29 different nationalities.

Learn more

People

Fleet Space Expands Presence In US With New Chief Revenue Officer

November 16, 2022

Blog

Kevin Ramani joins Fleet Space as new CRO, bolstering presence in the US and global markets to boost revenue.

Learn more

People

It is Rocket Science: CEO Flavia Tata Nardini Recognised by Pearcey Foundation

November 14, 2022

Blog

Fleet Space's CEO and Co-founder, Flavia Tata Nardini, wins the 2022 SA Pearcey Entrepreneur Award for her contribution to tech innovation and the Australian space industry

Learn more

People

Fleet Space Appoints Dr Hemant Chaurasia as Chief Product Officer

October 26, 2022

Blog

Fleet Space is delighted to announce that Dr Hemant Chaurasia has formally joined the company as Chief Product Officer (CPO).

Learn more

People

US ‘Nickel Hunters’ Talon and Fleet Pilot Satellite-Enabled Mineral Exploration Technology to Help Secure US Electronic Vehicle Battery Supply Chain

September 27, 2022

Blog

Fleet pilot satellite-enabled mineral exploration technology to help secure US electronic vehicle battery supply chain. Learn more.

Learn more

Minerals

ExoSphere

Fleet Space Technologies Announces Recognition as a Winner in the The Australian Good Design Awards

September 21, 2022

Blog

ExoSphere by Fleet® revolutionary Earth scanning technology was awarded “Best In Class” in the Product Design category, in recognition of outstanding design and innovation.

Learn more

Corporate

Rapid Basin Screening for Carlin-Type Gold Deposits Using Satellite Enabled Ambient Noise Tomography (ANT)

August 30, 2022

Blog

ExoSphere by Fleet®'s Ambient Noise Tomography (ANT) system offers a speedy and efficient solution for the exploration of Carlin-Type Gold Deposits.

Learn more

ExoSphere

Minerals

Fleet Space Announces Launch of Next Generation Centauri-5 Satellite on Space-X Falcon

August 30, 2022

Blog

Fleet Space's Centauri 5 satellite launch with SpaceX will improve mineral exploration efficiency and support Australia's growing space industry.

Learn more

Space

Fleet has obtained two ISO standards – 27001; Information Security Management and 9001 – Quality Management System

August 29, 2022

Blog

Fleet Space secures ISO 9001 and 27001, affirming commitment to cybersecurity and bolstering its global space industry presence.

Learn more

Space

Corporate

Hon. Susan Close MP Backs Space Industry Growth by Officially Opening New Fleet Space Technologies Expanded Australian HQ

August 16, 2022

Blog

Fleet Space HQ's official opening by Deputy State Premier, Susan Close MP marks ongoing commitment to innovation and growth

Learn more

Corporate

ExoSphere by Fleet® Earth Scanning Technology Successfully Trialed at Australian Lithium Exploration Project

August 10, 2022

Blog

ExoSphere by Fleet® Earth scanning technology successfully trialed at Australian lithium exploration project.

Learn more

ExoSphere

Minerals

Atlantic Lithium To Leverage ExoSphere by Fleet Solution For Geophysical Survey in Ghana, West Africa

April 4, 2022

Press Release

Atlantic Lithium to leverage ExoSphere by Fleet® solution for geophysical survey in Ghana, West Africa. Learn more.

Learn more

Minerals

Fleet Space Technologies to Revolutionise Mineral Exploration with Launch of ExoSphere by Fleet®

March 28, 2022

Press Release

Fleet Space Technologies unveils ExoSphere by Fleet®.

Learn more

ExoSphere

Flavia Tata Nardini Feature on 'The Australian' – Science Career: A Chance to Solve the World’s Problems (For International Women's Day)

March 8, 2022

Blog

Flavia Tata Nardini, CEO and Co-Founder of Fleet Space Technologies, shares her inspiring journey and the ongoing need for diversity in STEM fields on IWD

Learn more

People

Fleet Space Technologies Plots First Phase of Global Expansion by Establishing Presence in the United States

February 2, 2022

Blog

Fleet Space establishes first international presence in United States as part of their ambitious growth plans to secure planet-wide connectivity coverage.

Learn more

Space

Fleet Space Technologies Secures $26.4m (USD) in Series B Funding to Enable Global Satellite Connectivity for Internet of Things

November 17, 2021

Press Release

Fleet Space secures $26.4M(USD) funding boost for IoT nanosatellite technology, boosting investor confidence in their expertise in the Space Technology sector

Learn more

Corporate

Space

Minerals

Sorry, no results found.

.svg)

.svg)